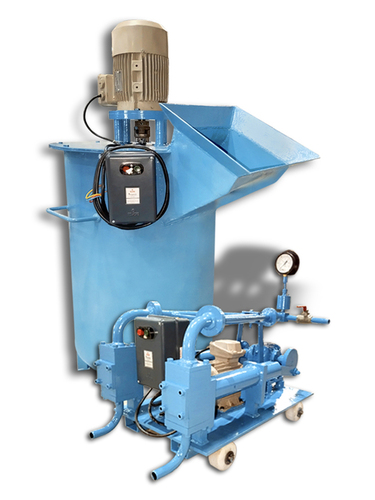

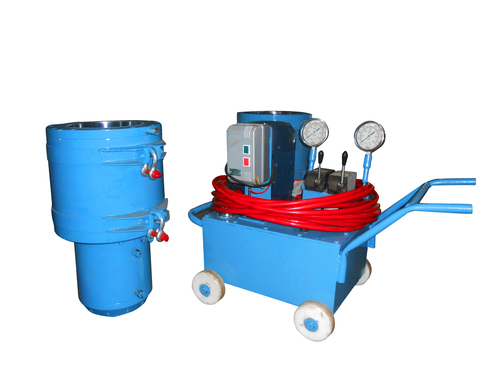

Electric Grout Pump and Agitator

Electric Grout Pump and Agitator Specification

- Accuracy

- High Grout Discharge Precision

- Control System

- Electric Panel with Manual/Auto Modes

- Technology

- Electric Motor Driven Pump System

- Automation Grade

- Semi-Automatic

- Machine Type

- Portable/Stationary Grout Pump Unit

- Surface Treatment

- Powder Coated / Painted Finish

- Power Source

- Electric

- Operating Pressure

- 0-40 Bar (580 psi) Approx.

- Features

- Efficient Continuous Operation, Easy Maintenance, Robust Construction, Integrated Mixing Tank

- Accessories Type

- Flexible Hose, Agitator Paddle, Nozzles

- Type

- Grout Pump with Agitator

- Material

- Mild Steel Structure, SS & MS Components

- Function

- Mixing and Pumping Grouting Materials

- Application

- Construction, Tunneling, Foundation Grouting, Dams, Bridges

- Voltage

- 220-240V / 380-415V, 50/60 Hz

- Dimension (LxWxH)

- 1100 x 700 x 1000 mm (typical)

- Agitator Motor Power

- 0.5 HP to 1 HP

- Weight

- Approx. 160-250 kg

- Filling Capacity of Hopper

- 50-100 Litres

- Pump Output

- 60-100 Litre/hour (Depending on Model)

- Mounting

- Mounted on Castor Wheels / Skid Base

- Pump Motor Power

- 2 HP to 3 HP

- Discharge Distance

- Up to 100 meters (Horizontal)

- Max Solid Size in Grout

- 6 mm

Electric Grout Pump and Agitator Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 3 Days

About Electric Grout Pump and Agitator

The prestressingtechnology is emerging to be a fast growing field in construction industryparticularly for mega structure like buildings, bridges, metro rails, flyovers,Via Ducts, nuclear power plants, LNG tanks, cement plants, thermal projectsetc.

JK Prestressing is a specialistagency in the field of prestressing to cater to a wide range of Post-Tension(Mono & Multi strand Anchorage system) & Pre tensioning system.

In order to guaranteethe best quality of service to all of our clients around the world we areequipped with all latest and modern machineries.

Because of workmanship is very essential tothe quality and durability. JKPC instructs its teams in properly installing andgrouting post-tensioning. Each year operators, prestressing installationspecialists, supervisors and engineers obtain qualification certifying their skillsto JK standards.

|

Surface Finish |

Hot Galvanized |

|

Material |

Iron |

|

Technique Used |

Post Tensioning Terminology |

Precise Mixing and Pumping for Demanding Applications

Designed for accuracy, this grout pump and agitator features integrated mixing tanks and agitator paddles, guaranteeing uniform blending of grouting materials. Its high discharge precision allows for reliable application in foundation work, dams, bridges, and tunneling projects, helping users achieve consistent results across varied construction environments.

Robust Build and Effortless Mobility

Constructed with mild steel and powder-coated or painted surfaces, the unit boasts both durability and resistance to harsh site conditions. With convenient castor wheel or skid base mounting, it can be easily relocated or stationed as needed, adapting to changing jobsite requirements without hassle.

Streamlined Operation and Flexible Controls

The pumps electric panel offers both manual and automatic modes, providing operators with flexibility and ease of use. Accessories such as flexible hoses, nozzles, and agitator paddles enhance utility, while semi-automatic operation reduces operator effort and ensures maximum productivity with minimal maintenance demands.

FAQs of Electric Grout Pump and Agitator:

Q: How do I operate the Electric Grout Pump and Agitator for optimal grout mixing and discharge?

A: Begin by loading grouting materials into the hopper, which supports 50100 litres. Set your preferred mode (manual or auto) on the electric control panel. The agitator ensures thorough mixing, and the pump delivers grout efficiently at outputs between 60100 litres per hour, enabling precise discharge over distances up to 100 meters.Q: What types of materials can the pump handle and what is the maximum particle size?

A: This unit is designed for grouting materials suitable for construction, tunneling, and foundation work. It can accommodate solids up to 6 mm in size, ensuring uninterrupted pumping without blockages and maintaining high discharge accuracy.Q: Where can I use this grout pump and agitator within civil engineering projects?

A: The machine is ideal for construction sites, tunnels, dam building, bridges, and foundation grouting. Its portability, flexible configuration, and robust construction make it suitable for diverse project environments across India and beyond.Q: What process does the machine follow in mixing and pumping grouting material?

A: The agitator motor first ensures thorough mixing within the integrated tank. Afterward, the pump motor drives grout through the flexible hose and nozzle, delivering it smoothly and precisely to the required location, as governed by operator settings on the control panel.Q: When is it advantageous to choose the electric model over other grout pumps?

A: The electric model offers efficient, continuous operation and high accuracy, especially suitable for extended projects requiring reliable performance. The integrated control system and semi-automatic function minimize manual intervention, enhancing productivity and safety.Q: What are the benefits of using a portable or stationary grout pump unit?

A: Choosing a portable unit with castor wheels simplifies site relocation and setup, while stationary mounting provides stability for large-scale tasks. Both configurations share robust construction, ease of maintenance, and adaptability for pumping tasks in various civil works.Q: How does the control system enhance operation and safety?

A: The electric panel allows switching between manual and auto modes, giving operators versatility in handling various job complexities. This reduces operational error, increases safety, and ensures consistent grout discharge according to requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Post Tensioning Category

Multipull Prestressing Jack and Power Pack

Price 150000 INR / Number

Minimum Order Quantity : 100

Operating Pressure : 700 Bar (10,150 psi)

Application : Civil Construction, Bridge Construction, Precast Concrete

Features : Portability, High Durability, Easy Maintenance, Leakproof Operation

Accessories Type : HighPressure Hose, Coupler, Remote Control Unit

Post Tensioning Equipments

Price 35000 INR / Number

Minimum Order Quantity : 10

Operating Pressure : Variable

Application : Construction Infrastructure

Features : High Durability Precise Performance

Accessories Type : Post Tensioning Accessories

Multi Strand Prestressing

Operating Pressure : Up to 700 bar

Application : Construction Bridges Precast concrete structures

Features : Durable efficient operation under high pressure

Accessories Type : Prestressing Accessories

Post Tensioning Parts

Operating Pressure : Varied depending on system requirements

Application : Posttensioning systems for bridges buildings and other structures

Features : Durable corrosionresistant precisionengineered

Accessories Type : Anchors and Wedges

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS