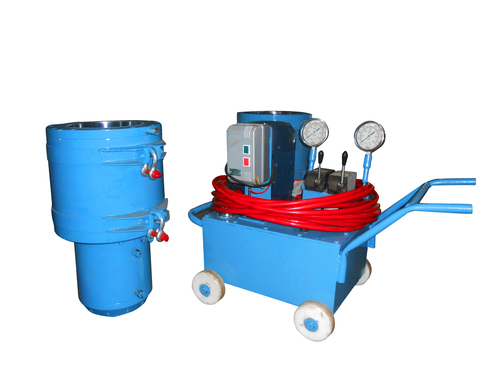

Multipull Prestressing Jack and Power Pack

Price 150000 INR/ Number

Multipull Prestressing Jack and Power Pack Specification

- Automation Grade

- Semi-Automatic

- Surface Treatment

- Powder Coated / Painted Finish

- Machine Type

- Multipull Prestressing Jack (Mono-strand/Multistrand)

- Power Source

- Electric Motor Driven Hydraulic Power Pack

- Accessories Type

- High-Pressure Hose, Coupler, Remote Control Unit

- Operating Pressure

- 700 Bar (10,150 psi)

- Accuracy

- 2% of Full Scale

- Technology

- Hydraulic Multipull System

- Features

- Portability, High Durability, Easy Maintenance, Leak-proof Operation

- Control System

- Manual and Remote Control Options

- Type

- Double-Acting Jack with Power Pack

- Material

- High-Grade Alloy Steel

- Function

- Tensioning and De-tensioning of Prestressing Cables

- Application

- Civil Construction, Bridge Construction, Precast Concrete

- Voltage

- 220V / 380V AC, 50Hz

- Sealing System

- High-Pressure Oil-Sealed Cylinder

- Weight

- Approx. 80 kg to 250 kg (Jack + Power Pack)

- Coupler Type

- Quick-Connect High-Pressure Type

- Stroke Length

- 150 mm to 300 mm (customizable)

- Hose Length

- 5 m 10 m (standard/custom)

- Motor Power

- 3 HP to 10 HP

- Ram Return Type

- Double-Acting Hydraulic Return

- Jack Capacity

- 30 Ton to 150 Ton (as per design model)

- Jack Color

- Industrial Yellow/Blue or as per order

- Oil Tank Capacity

- 25 to 100 Litres (depends on model)

- Safety Mechanism

- Pressure Relief Valve, Overload Protection

- Temperature Range

- -5C to 55C

- Cylinder Bore Diameter

- Varies with model (Typically 100 mm 250 mm)

- Compliance Standard

- Meets IS/BS/EN Prestressing Equipment Standards

About Multipull Prestressing Jack and Power Pack

Prestressing Material Divisions

The prestressing technology is emerging to be a fast growing field in construction industry particularly for mega structure like buildings, bridges, metro rails, flyovers, Via Ducts, nuclear power plants, LNG tanks, cement plants, thermal projects etc.

JK Prestressing is a specialist agency in the field of prestressing to cater to a wide range of Post-Tension (Mono & Multi strand Anchorage system) & Pre tensioning system.

In order to guarantee the best quality of service to all of our clients around the world we are equipped with all latest and modern machineries.

Because of workmanship is very essential to the quality and durability. JKPC instructs its teams in properly installing and grouting post-tensioning. Each year operators, prestressing installation specialists, supervisors and engineers obtain qualification certifying their skills to JK standards.

Precision and Power for Prestressing

This jack and power pack system delivers high-capacity tensioning with exceptional accuracy, supporting both mono-strand and multi-strand operations. Its modular design allows customization in jack capacity, stroke length, and power options, making it a dependable choice for diverse prestressing applications in construction and infrastructure projects.

Enhanced Safety and Durability

Equipped with overload protection, pressure relief valve, and a high-pressure sealed cylinder, the product prioritizes operational safety and longevity. Powder-coated or painted finishes on high-grade alloy steel provide excellent resistance against wear, corrosion, and harsh jobsite conditions, maximizing equipment lifespan even in rigorous environments.

Efficiency and Easy Integration

The hydraulic power pack, driven by an electric motor (3 HP to 10 HP), offers portability, easy setup, and low-maintenance operation. Quick-connect couplers and remote/manual control options ensure user-friendly integration on site, supporting efficiency and adaptability to specific project workflows. Accessories like high-pressure hoses and remote units further simplify usage.

FAQs of Multipull Prestressing Jack and Power Pack:

Q: How does the Multipull Prestressing Jack and Power Pack operate?

A: The system utilizes hydraulic power, combining a double-acting jack and electric motor-driven power pack. This allows for precise tensioning and de-tensioning of prestressing cables, with the operator choosing between manual or remote control for enhanced flexibility during use.Q: What are the main benefits of using a Multipull Prestressing Jack in construction projects?

A: Key benefits include high accuracy (2% of full scale), robust construction using alloy steel, reliable safety features, and compliance with international standards. Its portability, easy maintenance, and quick setup make it ideal for demanding environments such as bridge and precast concrete works.Q: When should I consider customizing the stroke length or jack capacity?

A: Customization is recommended when your project requires specific force outputs or cable extension lengths not provided by standard models. The manufacturer offers tailored solutions within the typical range of 30150 tons capacity and 150300 mm stroke length to suit varying prestressing demands.Q: Where can this jack and power pack system be utilized?

A: It is suitable for civil construction locations, bridge construction sites, and precast concrete production yards. Its adaptability and compliance with IS/BS/EN standards make it a reliable choice for both small-scale and large-scale projects in India and abroad.Q: What safety mechanisms are included in the equipment?

A: The system features a pressure relief valve, overload protection, leak-proof operation, and a high-pressure oil-sealed cylinder to ensure both operator safety and equipment longevity under high-load conditions.Q: How do I maintain the Multipull Prestressing Jack and Power Pack for optimal performance?

A: Routine checks of hydraulic oil levels, inspection of hoses and couplers, and cleaning the unit after use are essential. Regularly test safety features like the pressure relief valve, and follow the manufacturers schedule for oil changes and general maintenance to ensure durable and reliable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Post Tensioning Category

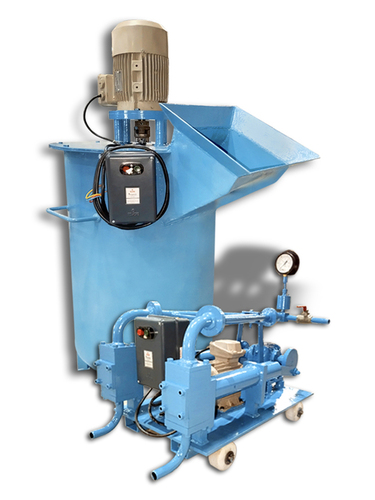

Electric Grout Pump and Agitator

Minimum Order Quantity : 10 Pieces

Automation Grade : SemiAutomatic

Application : Construction, Tunneling, Foundation Grouting, Dams, Bridges

Function : Mixing and Pumping Grouting Materials

Surface Treatment : Powder Coated / Painted Finish

Post Tensioning Equipments

Price 35000 INR / Number

Minimum Order Quantity : 10

Automation Grade : Manual

Application : Construction Infrastructure

Function : Reinforcement for Concrete Structures

Surface Treatment : Galvanized Anticorrosive Coating

Multi Strand Prestressing

Automation Grade : Semiautomatic

Application : Construction Bridges Precast concrete structures

Function : Tensioning and anchoring of multiple strands

Surface Treatment : Rust resistant

Post Tensioning Parts

Automation Grade : Manual

Application : Posttensioning systems for bridges buildings and other structures

Function : Securing and distributing tension in posttensioning applications

Surface Treatment : Galvanized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS